The Critical Metals Report: American Elements occupies a specialized niche in the minor metals and rare earth elements (REE) sector. Tell us about your business.

Michael Silver: American Elements was formed approximately 22 years ago. We supply essentially all metals on the periodic table and in every form that nature and current technology allow. In fact, we are the world's largest catalog for these materials. In the materials world, only one-eighth of the periodic table's metals are commercially produced as common metals in common forms. American Elements works with the remaining seven-eighths. For example, we produce a common metal such as copper, but at ultra-high purity or as a nanoparticle. We produce REEs in natural or synthetic form because they are in the "advanced materials" category. The same would apply to other critical metals such as REEs, refractory metals such as hafnium, scandium and the metalloids, such as germanium, indium and gallium.

TCMR: Which sector is your biggest customer?

MS: That is difficult to answer. There is virtually no industrial manufacturer we do not touch: General Electric, Siemens, Honeywell and DuPont all buy materials from us on a large scale. We supply every national lab in the U.S., as well as national labs in Europe, Japan, India, Brazil and Singapore. Hundreds of universities buy from us. We are involved at the research level all the way to container loads of materials that go into GE lighting, catalysts for companies such as Engelhard and W.R. Grace or electronic applications for Siemens, Hewlett-Packard and Intel. We also have a very large defense and military materials division working with companies such as Raytheon in the U.S. and BAE Systems in the U.K. To give you one example, we supply the proprietary propellant used in every medium- and small-caliber bullet used by the U.S. military.

TCMR: Over the last several years, there has been great concern in the mining industry over China's stranglehold on the REE market. Do you see that as being problematic or are the Chinese good partners for you in terms of acquiring the materials needed to manufacture your end products?

MS: I would say the mining community should be doing nothing but applauding China. All of these junior mines are being built today because of what China's regulations did to the price of REEs in recent years.

Before 2009, you could not have justified starting up a new rare earth mine. From World War II into the late '90s, there was a duopoly in the REE industry. There was what is now Molycorp Inc.'s (MCP:NYSE) facility at Mountain Pass, which was owned by Unocal. Then there was the French company, RhŰne-Poulenc, now called Rhodia Group (RHA:NYSE), which sold and distributed all Chinese REE production worldwide.

When Deng Xiaoping started pushing China to engage global capital markets in the late '90s, the Chinese began, as many early-stage industrializing nations do, by selling natural resources directly at prices that were about one-tenth of what the duopoly was selling at. As a result of China's entrance in the market, REE prices remained flat from 1998 to 2010 and traded within a very narrow range: lanthanum oxide was $4-6/kg, cerium oxide was $3-6/kg, neodymium traded between $18 and $22/kg.

However, around 2007 China also began using export quotas to gain some measure of control as to who could export REEs. This led to several other forms of export restrictions. Now, all REE manufacturers, including American Elements' joint venture partner in China, are basically under government control and the cost of REEs inside China is about half of what it is outside of China. Some now argue that what the government really cares about is creating a price differential for REEs inside versus outside of China, rather than the price itself.

REEs are not, and may never be, a tradable investment commodity. They are a business-to-business raw material used to produce end-use goods that have incredibly high value, such as cars and smart-phones. That is what makes them so important. Instead of caring about the REE mines themselves, which may generate hundreds of thousands of jobs in the U.S., we should consider the success of our makers of cars, smart phones, wind turbines, fluorescent lights and all the products reliant on REEs that generate millions of jobs. A nation cannot develop these industries if, at the end of the day, production costs are too high. The Chinese have a wonderful opportunity, in that they presently can produce all those goods at a lower price than the rest of the world, assuming such a price differential can be maintained. And that creates the real potential for other global manufacturers of these goods.

As to those looking to invest in the many junior mines going public these days, investors need to realize that China will always be in the position to flood the market with REEs any time it wants, as it did in 1998. China's almost unlimited supply of REEs will not change. The situation is analogous to the Middle East's position with oil. The 10,000-pound gorilla always dictates pricing. Of course, China dumping rare earths at this point is a highly unlikely event.

The junior mines certainly have an opportunity, but they sit on a somewhat shaky foundation because of China's supply dominance. Some junior mines will do well no matter what, some will have to play their cards right to succeed, others will struggle.

TCMR: Are you nervous about your ability to procure what your customers need, given that China is now your primary supplier?

MS: We operate on a day-to-day basis. We stay aware of the politics and deal with them as they come up. The world has changed on us now three times. We worked with the duopoly of Molycorp and Rhodia. Over the last 12 years, we were happy to be a direct supplier from China. Today, getting materials out of China means dealing directly with the government. Now, the junior mines are creating opportunities for American Elements because they provide us with additional sources. As a company, we are OK either way. We just have to understand how to make certain our customers can operate unhampered by frictions within the supply chain. I have found that companies are willing to pay what they need to for materials if they feel everybody else is paying the same price. Where China might take prices is not the issue.

The bigger concern is this potential price differential, how it might impact future global research and which countries will benefit from new high-technology development. Already, we're seeing major companies outside of China, in the U.S., Japan and Europe, devoting significant research dollars to finding ways to avoid using rare earths in their products. This is not good for anyone, particularly the Chinese. Similarly, the mere perception that any new product development will ultimately result in creating jobs only in China will have a chilling effect on government funding to develop of these industries outside of China.

TCMR: But there is huge pent-up demand for these products in developing nations, and in the BRIC nations (Brazil, Russia, India, China). Will the people there care where their cell phones, air-conditioning units and fluorescent bulbs are manufactured? Does the U.S. need to do more to see manufacturing and supply chain capabilities return here?

MS: That is exactly the scenario that we are dealing with. If there is a pricing differential, mere access to the materials does not matter. If you can buy neodymium at the old price of $20/kg in China, but have to pay $250/kg outside of China, you cannot bring manufacturing and jobs to your country because you lack access to raw materials at a price that allows you to compete globally in these high-tech markets.

You mentioned the BRIC nations. Almost all of the niobium in the world, 97%, comes from Brazil. Virtually all of the nickel comes from Russia or Canada. Russia certainly produces enough to be the 10,000-pound gorilla when it comes to nickel. India controls steel by virtue of the ArcelorMittal S.A. (MT:NYSE) acquisitions over the last decade. China controls REEs and a lot of other important metals.

Therefore, the big long-term issue is the domino effect China's approach to rare earths will have on nations that are also trying to develop. When other developing nations realize that they have a sovereign monopoly on a given material, they may also try to leverage it. For example, Brazilian producers sell GE niobium for use in its U.S. production facilities. Given the sovereign monopoly Brazil maintains on niobium, why not encourage GE to build its production facilities in Brazil?

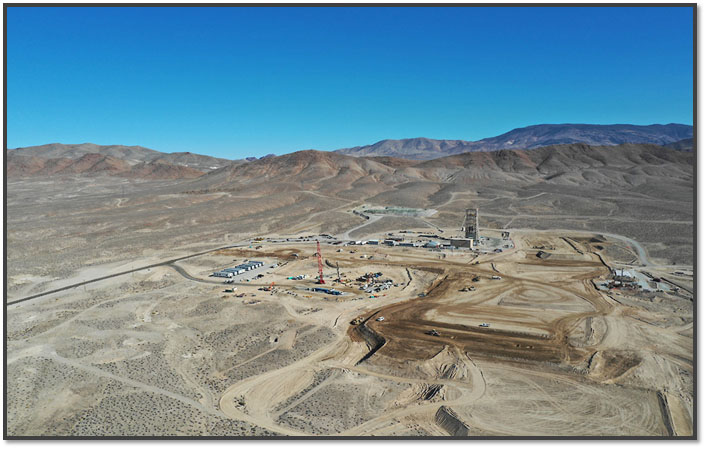

TCMR: In your view, is it a good thing to have these junior mining companies in North America developing projects?

MS: It could not be better. The U.S. has a great history of people like Henry Ford, Thomas Edison and Alexander Graham Bell creating industries. Alexander Graham Bell got the copper he needed from the copper mines of the U.S. Southwest. Ford went to Pennsylvania for coal and to Texas for oil. We had a huge base of the raw materials that were essential to the innovations developed at the beginning of the 20th century. Today, we no longer have the raw materials to execute on our 21st-century innovations. Junior miners can help change that.

This would not be an issue if countries with sovereign monopolies let the world know that they will always maintain an even playing field on raw materials prices. That only redounds to the benefit of the country that controls the materials. It allows every bright mind on the planet to innovate using the material that country controls without fear that their invention will just create jobs and wealth elsewhere. I do not believe that is an idealistic perspective.

TCMR: It's a capitalist perspective.

MS: Yes, it is. I expect to pay market prices, but in an open, transparent, competition-driven environment. I think, if the countries that control these materials take a look, they will realize the benefit and will make the world's inventors comfortable that they can innovate using any material and not get burned at the end of the day. We need to recognize how important it is for all of humanity to be able to contribute to technological development. Again, that may sound naÔve and idealistic, but I think it is not. The Chinese are famous for their long-term perspective and I believe this approach is in China's best long-term economic interest.

TCMR: Let's move to reality and some of the projects that you find interesting. Do you see any reason for an investor to be concerned about buying stock in a company that has more heavy rare earth elements (HREEs) versus light rare earth elements (LREEs)?

MS: I don't agree with the idea that companies that have mostly LREEs will not do well in the long term. I see three groups of junior mines. The first group is juniors that have large enough deposits of LREEs like cerium and lanthanum to be good, reliable long-term players. In this group, you have to first include Molycorp Inc., which has a lot of LREE in its Mountain Pass deposit, as well as a significant percentage of neodymium. But it is Molycorp's size and experience that really makes it valuable. Lynas Corp. (LYC:ASX) is in this group too. It controls huge deposits and, despite the unfolding production issues in Malaysia, eventually will do a really good job; it has a track record and great management. The third would be Great Western Minerals Group Ltd. (GWG:TSX.V; GWMGF:OTCQX), which controls two sizeable deposits, has maintained excellent relations in China and is very knowledgeable. Those three companies will survive and then some.

I call the next group of companies "boutique mines." These are the mines that are leaning heavily on the HREEs. At least three have really excellent deposits with great value, but we will have to see how long it takes them to come to fruition because of the permitting process. Ucore Rare Metals Inc. (UCU:TSX.V; UURAF:OTCQX) owns Bokan Mountain in Alaska. It may have a greater percentage of dysprosium than any other deposit on the planet. It also is near a Pacific seaport, giving cost-effective access to Japan and China, where almost all the REEs are presently used. Its CEO, Jim McKenzie, is smart and knows what the company has to do. Ucore has excellent relationships in Alaska; Senator Murkowski is 100% behind the development.

Another would be Tasman Metals Ltd. (TSM:TSX.V; TAS:NYSE.A; TASXF:OTCPK; T61:FSE), which owns a mine in Sweden. It is a really nice deposit, particularly its yttrium content. Yttrium has so many important applications. For example, you can't make a sparkplug without yttrium. Yttrium-stabilized zirconia is in bulletproof vests and in fuel cells, anything that requires strong ceramics or ionic conductivity. Tasman has a huge amount of yttrium in its deposit. The company has great management and also has a very good relationship with the Swedish government. On the logistics side, there are many users in Europe and there is a lot of desire for European-based REE sources.

Another boutique name is Hastings Rare Metals Ltd. (HAS:ASX). Its Hastings mine in Australia has a lot of HREEs; it's a very valuable deposit.

The third group is everybody else. There has been this big jump in the number of new entities with the strategic plan to find an REE deposit, go public and then begin the permitting process. Simply establishing good relationships with the local government can positively impact the value of these stocks today. Those stocks will, I think, do what the owners anticipate: become more valuable as they get closer to being able to actually mine ore. In this group, I encourage vertical integration, using the raw material they have access to as a strategy to cost-effectively produce the finished goods that require that material. Thus, rather than generating a profit by selling at the high global prices that may be established by a sovereign monopoly, they rely on their low raw material cost to compete in the end-use product.

TCMR: A few of these companies are doing that.

MS: A lot of them, actually. Hitachi just cut a deal in Australia. Molycorp bought a wind turbine manufacturer in Boulder, Colorado, as well as Neo Material Technologies (NEM:TSX), which allows Molycorp to further execute on its mine-to-magnets strategy.

TCMR: Before we end, let's go back to American Elements. You founded the company in 1993. How would you describe your growth path?

MS: It has been a parabolic, logarithmic curve upward. In the last five to six years, the company has grown tenfold. We will double this year, as we did last year. What I had hoped is actually happening: high-technology is coming to the fore and people are realizing materials nobody considered important before are now essential because we are learning to work with them. I remember no more than five years ago my mother, who is a very successful investor, telling me that she had to keep explaining to her friends that I wasn't in the "rare herb" business. Now, all of her friends are asking her which REE junior mine they should invest in.

TCMR: Thank you for your time.

Michael Silver is CEO of American Elements, a global manufacturer of engineered and advanced materials. He is an expert on rare earths and other critical metals such as lithium, indium and tellurium. Mr. Silver's expertise includes firsthand knowledge of the supply chain from mine to finished goods and the scientific applications that make these elements important. He is considered a pioneer in the fields of nanotechnology, materials science and alternative energy. The company has operations in Los Angeles; Salt Lake City; Monterrey, Mexico; Baotou, China and Manchester, U.K. In 2011, American Elements cosponsored 74 industry and academic conferences.

Want to read more exclusive Critical Metals Report articles like this? Sign up for our free e-newsletter, and you'll learn when new articles have been published. To see a list of recent interviews with industry analysts and commentators and learn more about critical metals companies, visit our Critical Metals Report page.

DISCLOSURE:

1) Sally Lowder of The Critical Metals Report conducted this interview. She personally and/or her family own shares of the following companies mentioned in this interview: None.

2) The following companies mentioned in the interview are sponsors of The Critical Metals Report: Ucore Rare Metals Inc. and Tasman Metals Ltd. This interview was edited for clarity.

3) Michael Silver: I personally and/or my family own shares of the following companies mentioned in this interview: None. I personally and/or my family am paid by the following companies mentioned in this interview: None.